Features of Glass Printing Machine:

Elevated Productivity

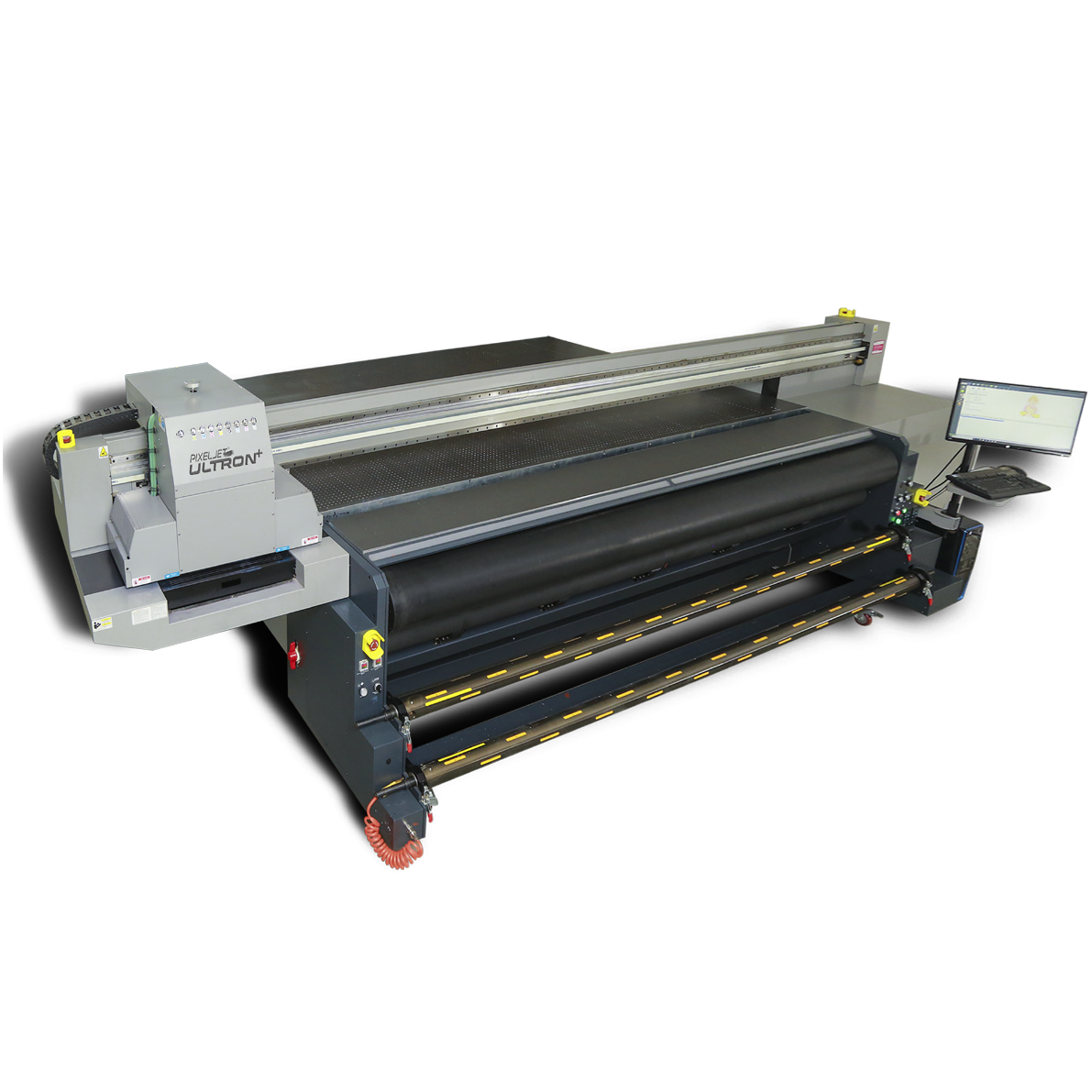

Pixeljet UV Hybrid printers (example : Glass Printing Machine) are high-speed LED UV curable inkjet systems which are idle for short run to high level production of multiple jobs with variety of sized media. It offers media edge-to-edge printing that eliminates the need of extra finishing step, saving time and money. Thanks to the multilayer printing feature the Pixeljet UV hybrid printers print several color and white ink layers in one run.

![]()

Pixeljet UV printers (Glass Printing Machine) are workhorse and can deliver printing speed of up to 450sqft/hr. (Depends on print head and colour configurations)

![]()

Superior Print Quality

Pixeljet UV Hybrid Printers can print on practically any rigid and roll to roll material. They deliver exceptional print quality on a wide variety of indoor and outdoor media such as corrugated boards, plastics, acrylic, glass, foam boards, exhibition panels, wood, aluminum, MDF, PS materials and wide range of flexible media. White ink and six colors with RICOH Industrial grade print 7-35 pl print heads allow it to deliver prints that will give you and your customers a competitive edge. The high-density color printing function makes prints even brighter, intense and vivid. Products printed by UV printer have many advantages such as water-proof, anti-scratch, abrasion resistance and thus it is the best Glass Printing Machine.

![]()

UV LED Print Technology

- Equipped with powerful, UV LED lamps for the curing process, the Pixeljet hybrid printers come with a number of economical, ecological and business-generating benefits:

- LEDs are cool and have minimal heat output, which is why they enable you to print on wide range heat-sensitive substrates.

- LED lamps eliminates lamp warm-uptime due to instant switch on and off feature that results in faster operations and higher productivity.

- LEDs have minimal energy consumption, which leads to significant power savings.

- LEDs have last for at least 5,000 hours each. They generate a consistent output throughout that period with no lamp change downtime or any consumable lamp costs.

- UV LED lamps don’t contain mercury, there is no need for mercury disposal or any related costs. Also, LEDs don’t produce ozone gas that needs to be extracted by ventilation.

Unlimited Applications

![]()

With Pixeljet UV Hybrid printers you can attract new business with a wide variety of applications: banners, posters, signage, displays, exhibition graphics, POP & POS, mock-ups, backlits, frontlits, self-adhesives (labels), best as glass printing machine. Also niche applications: DVDs, wood, art reproductions, personalized objects, party gadgets, as well as architectural and interior decoration, ceramics, glass printing machine… Because any material up to 100 mm thickness can be printed…means endless possibilities.

![]()

Benefits:

- Hybrid design allows more versatility

- Rigid and flexible both the media can be printed easily

- Greener and more cleaner printing with UV technology

- Low maintenance cost

- Faster production times

- Lower cost

- Easy customization

- Consistent print quality

Glass printing machine: Glass printing machines from Pixeljet® are ideal for product customization. The Pixeljet® Velocity Flatbed Printer is a high volume versatile UV flatbed printer which can print on unlimited applications. The Optional varnish not only enhances the visual quality but also creates the tactile attribute of graphics. Users are able to apply varnish directly on graphics via print heads as either an allover coating or as a spot-highlighting, giving your printings more vivid and brighter finishing. This are the best glass printing machines in the industry.

![]()